Southern Visitors To See Combined RADAN Software

Visitors to the RADAN stand at the UK’s Southern Manufacturing Exhibition will see how the 2015 release of the sheet metal software combines all aspects of it for the first time.

A number of the 180 enhancements in RADAN 2015 help bring all aspects of the software together – CAD/CAM, Radbend, Radm-ax, Radtube and the logistics products. “When people think of RADAN they think of the world’s most powerful sheetmetal CAD/CAM software,” says Product Manager Olaf Körner. “But RADAN is actually a whole suite of connected products.

“For example, there is a major connection between 3D in CAD/CAM and the Radbend press brake software. When manufacturers unfold a model they need to know how the bend process will be affected further down the production line.”

This is aided by strengthened 3D translation procedures, which he says import information more consistently. The routines for automatically calculating the thickness of imported parts have also been redesigned giving faster and more accurate results. Automatic face selection now applies to unfolding, and there is a simple way to manually specify the top face much earlier in the process. “Telling Radbend at the 3D stage which is the protected face ensures the visible face of the part is scratch-free.”

The bend parameters used by RADAN 3D to unfold parts can now be changed using a new editor in the Unfolding Dialog, by simply sliding points on the graph to adjust the values.

Visitors to Stand T80 at the show, at FIVE, in Farnborough, between February 10 and 12, will be able to see on-screen demonstrations of a number of the new and enhance functionality in RADAN 2015.

Nesting

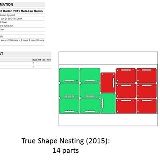

For nesting near-rectangular parts, the user can select the true-shape option and the nester will automatically apply rectangular nesting where appropriate, ensuring the best result. “In previous releases, while the rectangular nester found better nests for near-rectangular parts than the true-shaped nester, the user had to disable true-shape nesting to achieve the desired result.”

RADAN now creates a more compact nest than ever before, including compensating for centrifugal placement – the technique of placing parts as far removed as possible from the centre of the sheet. Olaf Körner says: “This potentially leaves a large gap in the middle of the sheet, but the compacting functionality offers more off cut areas, and is used on all nests.”

Material Handling

A number of important machine automation functions are built into the software, including significant enhancements to part removal. “When using a part picker it’s vital that the instructions to the machine allow the part and scrap to be removed safely and securely.

“In RADAN 2015, we’ve increased the amount of validation each Pick instruction requires against a number of parameters. Key suckers can be defined on the picker, and data introduced to the machine definition file, defining key suckers that must be turned on and over the metal when picking.

“Considerable work has gone into ensuring that RADAN understands the loading and removal process and what the machine is capable of. As well as calculating the sucker lift, we must be sure the part won’t bend and hit the machine while it’s being moved to its storage area.

“When using a part picker to load sheets the sucker selection is now managed by the software rather than the postprocessor.”

Another important safety feature is included with the introduction of the Scatter option, which moves the head a specified minimum distance away from each part after cutting, instead of moving to the next nearest part. “This prevents heat build-up when profiling, and sheet deformation while punching.”

Radbend

As well as a new option to use a link from Radbend to RADAN 3D to create a heel tool by using the 3D boolean operations on the tool profile and heel profile, Radbend has been strengthened in its control of the hemming process, by specifying the central face as being either above or below, and in the logistics of the press brake operations.

“For example, there is now the option of re-using tool set-ups if the same type of part could share the same setup, minimizing tool changes.”

Users now have more control over Radbend, enabling them to change a number of settings early in the process. “Operators often try a different set of finger stops, and transfer tool set-ups from one press brake to another. They can now do all that onscreen. And back-up and restore functionality protects the original settings, so users don’t need to be afraid of trying something new.”

Olaf Körner concludes: “RADAN constantly provides additional functionality in areas the industry is trending towards – 3D and automation– as the latest release shows.”