Workflow Simplified With New RADAN 2020.0

Automated and refined processes save time and admin

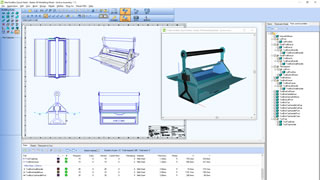

Olaf Körner, Product Manager for RADAN says: “After introducing a strong enhancement to our nesting engine last year, users have increased their operation of the automatic nester. The reporting is really powerful, and the number of mouse clicks needed has been reduced by around half, to use automatic nesting, or to work on a 3D model – the workflow is so much easier.”

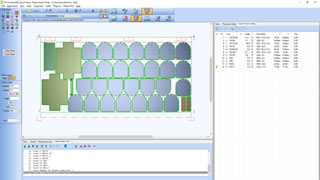

The new quick nest mode in RADAN 2020.0 provides a more visual interface, with limited upfront setup for projects. And a redesigned new project dialog allows users to ‘get nesting quicker’. Time benefits can also be achieved with machine specific projects and templates. Olaf Körner says: “If a user wants to begin nesting quickly, we’ve made it much easier to get started, with fewer questions and machine specific templates. The template contains automation – for example, a fiber laser template will switch to your correct laser machine and put in all the settings needed.”

As well as a quicker start to projects, it is also easier for users to pick up on previous projects. The new streamlined mode benefits from reduced mouse travel and an autosave function so that work is never lost. The ease of use ensures the software is simple to learn and allows more complex projects to be completed efficiently.

Complex projects can also be achieved using the new punching tool type. Punching plays an important part of the manufacturing process, and he says customers are getting more creative with their tooling for punch presses, to set them apart from lasers. Now there’s a new tool type for flattening features in the tool editor.

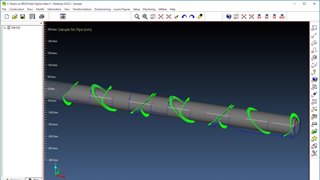

Radtube sees further improvements to the popular common line cutting feature, added in the previous release. Users can now optimise the nest either by material usage or by cycle time. When optimising the cycle time, the nest starts looking for common cuts more aggressively. “It doesn’t sacrifice all the material usage, but does look harder for opportunities to use common line cutting. This gives the customer a choice between using as little material as possible or optimising the cycle time.

“As common line cutting is becoming increasingly popular, customers asked us to allow their old legacy parts to be nested for it, too. They want RADAN to assume those parts can be common cut, if it’s safe. So we’ve brought in automatic common cut selection on legacy parts, giving more automatic common cutting.”

Radtube reporting has also been improved to include QR codes, bar codes and images, making the recognition of parts simpler and more accurate. The reports can be outputted automatically and in the required format.

In this release, Radquote has been enhanced with many updates; a highlight being the new nesting engine for material calculations. This feature has the ability to increase the number of orders won due to its accurate and achievable estimates. As soon as a quote turns into an order, Radquote automatically exports all the information needed, in the form of a PDF file for records; for emailing to the customer as an order confirmation; or as data in CSV or text format. This can be seamlessly linked to the company’s ERP/MRP system.

A new Radquote feature, Customer Specific Import Template, allows information such as DXF files to be automatically analysed according to the specific customer by setting up a template. “This can greatly improve the workflow, as without it, the file would need to be manipulated, which can be time consuming.

A default delivery time can also be added automatically to the quote along with a calculation for delivery costs based on a new ‘distance’ field for customer data. “As delivery costs will be more for a customer who’s 200 miles away, than for a customer just 20 miles away, when setting up a customer in Radquote you can now specify how far away they are. This is used in a formula to calculate, with the order weight, the total delivery costs.”

Radbend now has additional monitoring in place which checks the unfold geometry in a number of stages to ensure it is manufacturable. Olaf Körner explains: “For example, automatic checks can be carried out for holes too near to bends. Analysing the part, we can see whether the design is manufacturable in terms of whether any holes in the part are going to be deformed by the bending process.” Further checks have also been added to support intermediate bends, breaking down the process into two steps where needed, to ensure accurate results. Previously this could only be accomplished by physically changing the model and making different bends and stages; therefore this new function saves a considerable amount of time.

Overall RADAN 2020.0 benefits from further upgrades to workflow, increasing efficiency, saving time and optimising resources. “Manufacturers are getting real benefits from the software which has the ability to connect seamlessly to their ERP/MRP software. Achieving results more naturally and quicker, with much less manual input and fewer mouse clicks, not only saves time but also ensures the software is easier to use and learn. The automatic nesting algorithm will allow users to be more creative in using their material due to quality layout proposals, and the option of making different decisions on sheet sizes and manual nests.”