New RADAN Module Turns Customer Order Data Into Nests

One of the world’s most powerful sheet metal CAD/CAM software systems, RADAN, has launched another of its logistics modules, further automating the method in which customers can bring data into their system.“The new Radmanager is vital for RADAN to integrate more fully into a company’s complete I.T. structure,” says RADAN Product Manager Olaf Körner. “Traditionally, when people think of RADAN they think of CAD/CAM. But it’s actually a whole suite of connected products, and Radmanager is a simple way of entering customer order data and turning it into nest projects within RADAN.

“In particular, this enables subcontractors to combine parts from different customer orders into one nest project to maximise efficiency and material usage.”

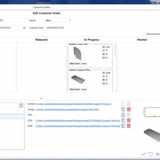

There are three specific aspects to Radmanager: Parts; Customers and Orders; and Nest Creation.

Firstly, information about the parts a company manufactures is stored, so repeat orders can be easily entered. Part data can be gathered from existing RADAN part files, or entered manually before the part is drawn. “Additional details, such as pictures, related CAD files and manufacturing data, can be attached to the part, so there’s no need to enter data repeatedly every time the component is manufactured.”

Secondly, details about customers can be entered, in addition to the orders they place. Each order can contain multiple parts, and the status of the order can be seen at a glance, before opening the order to drill down to more detailed information showing how the order is progressing. “Data can also be received from an ERP system via a CSV file, speeding up the operation and avoiding the need for duplicate data entry, which reduces mistakes caused by keying errors.”

And thirdly, RADAN nest projects can be created to meet any criteria. “A manufacturer may want to nest everything with a particular order-due date, or nest all parts made from a common material and thickness,” says Olaf Körner. “The user interface makes it easy to find the group of parts meeting the criteria and put them into a nest project ready for cutting.”

Once a nest project has been set up it can be processed in RADAN in the normal way. Any changes to the quantities of parts nested can be sent back to Radmanager to allow any components that were not nested to be added to another project. “This helps create nest projects without generating remnants which would otherwise need to be managed separately.”

Parts that are scrapped during production can be manually recorded against the customer order, allowing replacements to be nested as soon as possible.

“Overall, as Radmanager has direct links with RADAN CAD/CAM and can communicate easily with ERP systems, it is effective technology for transforming customer orders into nests. It streamlines the work flow of engineering parts and creating work orders.

“Manufacturers will be able to easily create nests for multiple orders, maximising efficiency and sheet utilisation, and manage their customer orders through the nest production process.”

For more information, please visit the Radmanager page:

http://www.radan.com/processmanagement/radmanager