RADAN Reaches The Heights for Health and Safety

The 3D modelling capabilities of the world’s most powerful sheet metal CAD/CAM software, RADAN, played a major part in developing a new product that is helping industry and commerce comply with health and safety regulations.

With the use of stepladders no longer being acceptable for changing light bulbs and other tasks that are out of reach without some form of elevation, Bison Products Ltd has created a powered low level access platform. The X-Step is the smallest scissor lift in the world, and is an efficient alternative to podiums and scaffolds for working at heights of up to around three metres.

Most powered access platforms are difficult to manoeuvre and can often be moved only by forklift. However, the X-Step is easily pushed through doorways, and can even be lifted safely by three people. Since its introduction into the marketplace a few months ago it has become a firm favourite with hire companies like Speedy Hire, Hire Stations and HSS for hiring out on a short term basis.

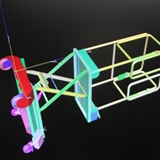

John Haworth, Director of Bison Products, also owns Norlec Sheet Metal, the company which manufactures the X-Step. Once the market need was identified, the team at Bison and Norlec designed the scissor-activated platform to reach the heights most employers need. Engineers used Inventor and RADAN 3D to create models of the 35 separate components, and then the full 3D working model, which was amended on screen instead of making the physical product and trialling it.

When it had all been proved out, engineers began the 2D development of the flatblanks, creating the 2D symbols in RADAN, and then passing the project to the production team to produce programs for punching and lasering.

“Instead of having to draw the parts in 2D, then flatten it out and create the symbols, the 3D working model saves a lot of time and money. New products sometimes require three or four actual prototypes before they’re right, and that can mean days of manufacturing and cutting, and a considerable amount of wasted material. The onscreen simulation meant we didn’t have any of that.

“This all gives a much faster time to market from the initial concept through prototype to the final production process.”

RADAN 3D also gave them the opportunity to create a floor sander from sheet metal, after the initial concept was for a steel tube product. “That came about purely because we could design it in RADAN 3D,” says John Haworth. “It meant we could design the final product to fit our sheet metal manufacturing process and give a much more cost effective design for manufacture.”

The RADAN 3D software focuses on the rapid creation and modification of 3D sheet metal parts and assemblies. Unfolding parameters can be controlled independently of the geometry, based on the actual tooling to be used in production. This leads to more accurate flat blanks, more accurate folding, and ultimately a higher quality product.

Then comes the nesting. “We have many different components for many different products, so we nest multi-components in the same thicknesses from a wide variety of jobs, not just the X-Step. Materials are a major cost in what we do, so the more of each sheet we can utilise the better – it makes us much more cost effective to help us compete with low cost manufacturing from abroad.”

Norlec’s cutting is done on two lasers and two punch presses – all Trumpfs. Both lasers have auto-loading, and because the more powerful of the two, the 4 kw, is fully automated, they frequently load around three tonnes of steel and run it on a lights-out basis, confident that the RADAN program will perfectly control the machine’s automation capabilities.

Lights-out working is also a regular occurrence on the punching operation, thanks to full auto load/unload and part-picking. “We have a large area to handle the part-picking, so we either drop large components into boxes or put them on pallets and separate them in stacks. RADAN plays a major part in getting the programming for that absolutely right.”

Automation is an essential aspect of Norlec’s philosophy, both for the actual manufacturing on the shop floor with RADAN, and for their production control system and the general running of the business, through RADAN’s sister – and fully integrated – software, e2i.

e2i

“The fact that e2i has full estimate to invoice capability, with all other office administration and management functions in between, and is linked to RADAN CAD and programming, is a major plus for us,” says John Haworth.

“Sometimes in the past, it could take days from receiving an enquiry to actually getting the job into production. With e2i that’s been reduced to, literally, hours if necessary. “Doing the estimate in e2i sets up the basic route and bill of materials, then it’s fine-tuned by our engineers, the symbols are created and it goes into the manufacturing system.”

He says in order to produce the quote they either undertake the drawing themselves or import a drawing supplied by their customer. “That gives us the basic material and size in e2i, which is a huge advantage over the estimator having to work it all out. Because we’ve got all our materials in e2i’s materials database, we just input the material we want for this particular job, put the operation in, and it generates the cost. The mark-up, or cost recovery, is also preset in e2i, so that gives us the selling price. And e2i gives us appropriate quotes for different batches, meaning it’s just as easy to quote for 10-off, as it is for 100-off.”

The quote is sent out to the customer electronically from e2i, which also automatically monitors the jobs they win and those they don’t. “Each one we win is loaded as a contract and passed to engineering to prove off the routing, add jigs and fixtures, and ensure that both the bill of materials and symbols are correct. e2i also looks at the material required for the job and places the order.”

Having generated the route card which is then used to manage all manufacturing data, e2i produces the delivery note, and after the consignment is despatched to the customer, it creates the invoice.

“Everything is done on the one system, instead of having to import data into a different system, or manually input it, which can lead to errors. Automation on the shop floor, and in our administration and management of the company, both of which are controlled by RADAN, gives us a competitive edge over foreign competition who rely on cheap labour. We get a much more accurate product, at a reduced cost, and with shorter lead times.”