Monti, Inc.

Monti, Inc., tier-one supplier for the electrical industry, cut programming time by 60 percent, nesting time by 80 percent, and laser-cutting time by 30 percent with RADAN

Having grown from a small, developing business to a tier-one supplier for the electrical industry, Monti, Inc., has learned a thing or two about sustainability over the course of nearly 50 years.

Today, the company is a supplier to such notable OEMs as Siemens, Schneider Electric™, and Eaton, and operates plants in Ohio, South Carolina and Michigan. From one-off prototype and repair jobs to high-volume production, Monti, Inc., makes everything from copper and aluminum conductors to electrical insulation, steel components, and more.

“Our equipment can make about anything, but 90 percent of what we do day in and day out is for the electrical industry,” says Plant Manager Nick LaVigne, who has been with Monti, Inc., for nine years, and is based in its Greenwood, South Carolina, plant. “We work with the large OEMs, but we also take on small projects to help assist local businesses; we’re here to help.”

The company takes its core values seriously, including its mission to deliver on customer service in ways that its competition doesn’t. “We value responsiveness to our customers’ needs, and that’s where we’re better than most. In many cases, we can complete expedited projects faster than our competition can even quote the job.”

Long-term sustainability is among the company’s values, and that entails everything from lasting customer and employee relationships to ongoing process improvement. “We’re always looking to make our quality better, improve our safety, and improve our processes to become more efficient and more adaptable. We’re continuously looking for new technology, and year over year we spend a large percentage of our profits on new equipment.”

It was this dedication to sustainability that compelled the company to make the switch from its former computer-aided-manufacturing (CAM) system to the RADAN solution for sheet metal, by Vero Software, in 2014.“We tested our software options and knew that RADAN was the one for us because we saw the customization that it offered.”

Nick LaVigne, plant manager

“We knew that we needed higher efficiencies and that our old software was very slow and cumbersome,” LaVigne says. “We tested our software options and knew that RADAN was the one for us because we saw the customization that it offered.”

Monti, Inc., makes products from materials such as copper and aluminum; stainless, galvanized, and hot and cold-rolled steels, and even insulation and plastics. It produces parts that range in size from those that can be held in the palm of the hand — similar to washers — to brackets and panels as large as 5’ X 10’.

“RADAN has the ability to program for all the material types that we use on our laser, and it can program and create nests quickly, which is something that we really needed.”

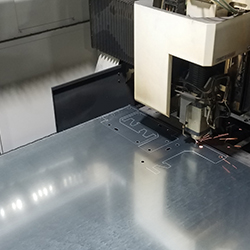

When Monti, Inc., purchased RADAN, it was running four CNC lasers at two of its plants. Today, it operates a total of three Mazak lasers at its Cincinnati and Greenwood plants and performs some lights-out laser cutting at the Cincinnati location.

“It’s a testament to how we’ve integrated our facilities, expanding and spending money on more technology,” LaVigne says. “We do a lot more with less equipment, and with better quality and better speed.”

The company has seen an up to 60 percent decrease in overall programming time at both plants, with an 80 percent reduction in the time it takes to generate nests. It has also achieved a 30 percent reduction in laser run time at both plants, due to higher-efficiency toolpaths.

Time is money in manufacturing, so the savings in man-hours and machine time quickly add up. Monti Cincinnati has reduced programming time by 1,344 hours per year and laser run time by 6,454 hours per year, while Monti Greenwood has reduced programming time by 448 hours per year and laser time by 268 hours annually.

LaVigne credits RADAN’s optimization tools, including automatic tooling and specialized cutting paths, for the dramatic improvements. “We set up all of the automatic technology in it so that it easily takes less than two minutes to program a part,” he says.

LaVigne and his team also take advantage of the flexibility of the software, which enables users to edit automatically generated nests for greater control. “Most of the time, the automatic nesting is exactly what we want, but we are able to tweak it, add parts, or make other adjustments. For instance, if the customer comes back and adds parts, we can insert them into the nest very easily.”

The company also uses RADAN to customize the way that it processes scrap parts. For instance, if a part has a rectangle cut from the middle of it, it can be picked up and thrown away, or RADAN can be programmed to cut it into 1” X 1” pieces so that it falls through the table. As many of the sheets at Monti, Inc., are 4’ X 8’, or 5’ X 10’, RADAN is often programmed to cut large and unwieldy pieces of scrap into 24-inch-wide sections to be more easily collected manually.

“RADAN has very good, quick settings for how you create your scrap and how you cut your sheets into scrap sections at the end of the program, so you can customize your drops,” LaVigne says. “In some cases, we’ll have RADAN cut everything on half of the sheet and then cut the other half into 24-inch sections to be put into a pile of partials. RADAN can also track how many pieces you have on the shelf.”

RADAN helps LaVigne and his team track the shapes cut from scrap material and drops by assigning lot numbers or sheet numbers to the leftover materials. “We’re getting much better material yield and we’re able to stock our drops in a much more organized way. We used to spend 10 minutes programming how to cut pieces just to throw them away, but RADAN does that perfectly when it’s nesting. Our nesting is also optimized by automatically nesting parts in the scrap areas of larger parts.”

The team at Monti, Inc., utilizes a RADAN network key so that each programmer can seamlessly access jobs and work collaboratively without communication lag time. LaVigne notes that the solution’s ease of use has paved the way for new users to quickly become proficient at programming without having to overcome too challenging a learning curve.

“It’s truly a testament to the software that, when it’s set up upfront, it really is simple to use,” he says. “The software is amazing, and we have no plans to review new software any time in the near future.”

About the Company

Name: Monti, Inc.

Business: Tier-one supplier to the electrical industry

Website: monti-inc.com

Benefits Achieved

- Sixty percent decrease in overall programming time

- Eighty percent reduction in time needed to generate nests

- Thirty percent reduction in laser run time due to higher-efficiency toolpaths

Comments

“We tested our software options and knew that RADAN was the one for us because we saw the customization that it offered.”

Nick LaVigne, plant manager

.jpg)

.jpg)